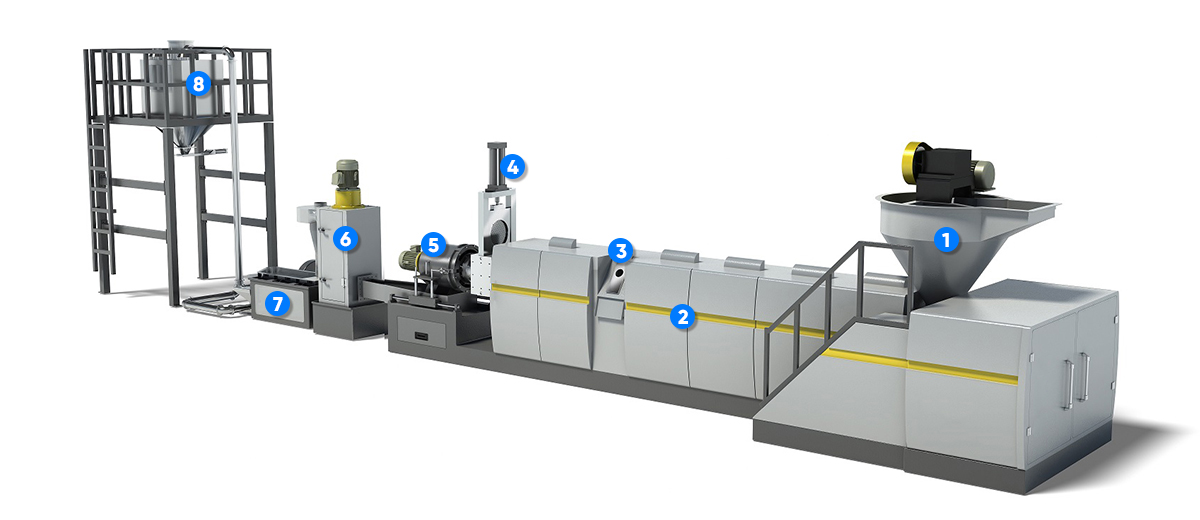

One Stage Force Hopper Feeding Plastic Recycling Machine

A valuable selection for clean materials, without preheating section for feeding device, this reduces the power consumption.

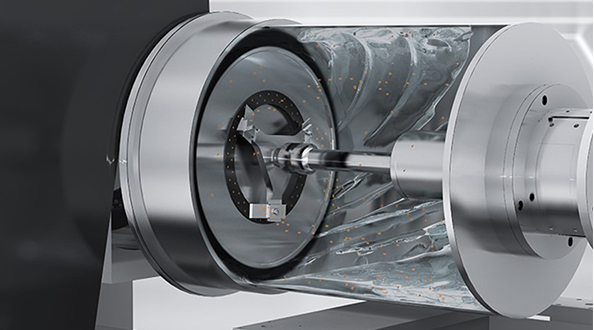

The axle is made of special steel with heat treatment. More tenacity and allows the materials to be fed sequence stably and is also anti-bridging.

Energy cost savings up to 10%

Labor cost is reduced as only 1~2 operators are needed to operate the whole plant.

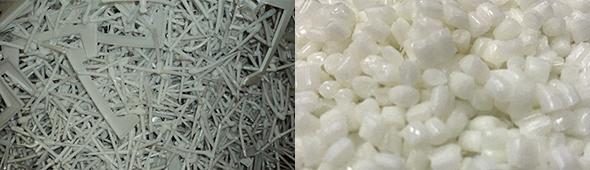

The pelletizing system can equip with hot die face cutting water cooling system or Strand (Spaghetti) pelletizing system depends on the material property and material Melt Index.

PE, PP, PS, ABS, HIPS, PET and more.

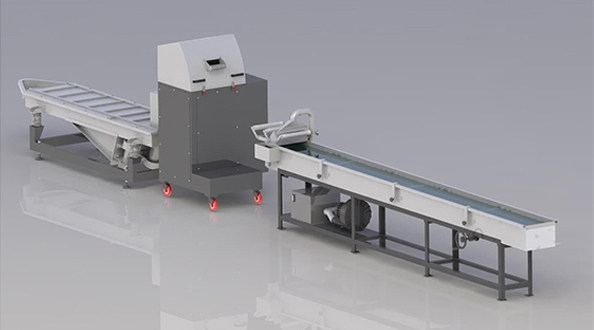

Recommend mainly for In-house, Post-industrial clean plastic rigid materials, including crushed bottles, crushed industrial waste and injection materials.

| Model | RE-85 | RE-100 | RE-125 | RE-150 | RE-175 |

|---|---|---|---|---|---|

| Main Extruder | ∮85mm | ∮100mm | ∮125mm | ∮150mm | ∮175mm |

| Main Motor | 75 HP | 125 HP | 150 HP | 200 HP | 350 HP |

| Output (kg/hr) | 150-250 | 250-350 | 400-550 | 550-700 | 750-1000 |

| Optional Devices: Belt conveyor, Plastic crusher, Horizontal mixer tank, Screw conveyor, Masterbatch feeder, Vacuum Pump, Doble vented barrel, Dual piston filter, Cooling tower with tank for water circulation. |

|||||