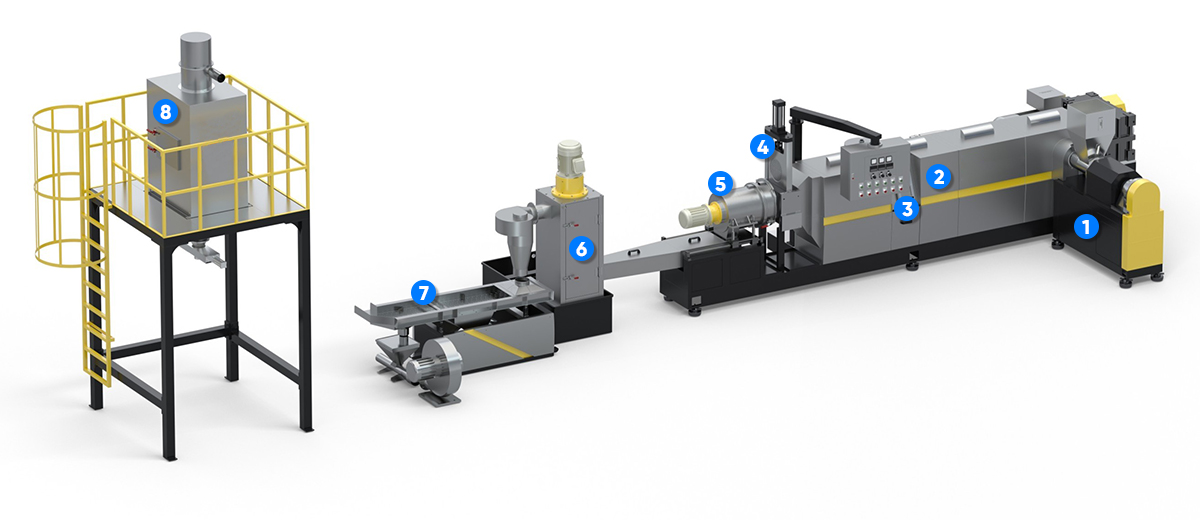

One Stage Force Side Feeding Plastic Recycling Machine

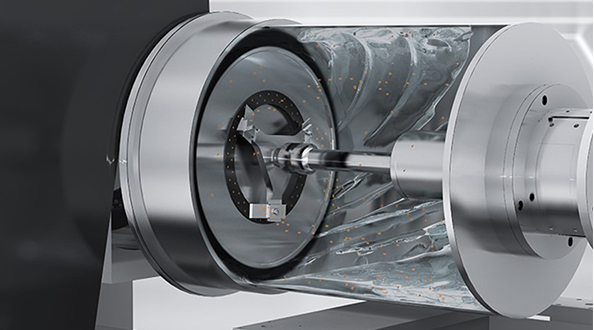

The force side feeding device creates a very stable feeding flow. With stable feeding, the main screw is always fully loaded with materials, which ensures the highest output performance. Increase the output capacity by up to 50%.

The feeding control system monitors the ampere and controls the feeding speed automatically. Only 1~2 operators are required for an entire plant.

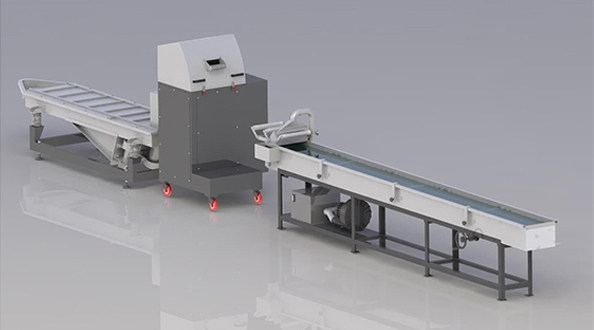

The pelletizing system can equip with hot die face cutting water cooling system or Strand (Spaghetti) pelletizing system depends on the material property and material Melt Index.

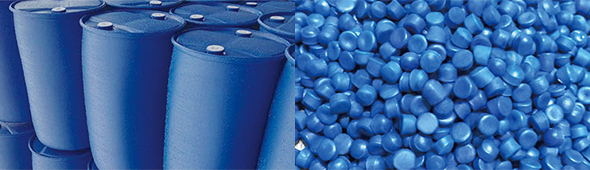

PE, PP, PS, ABS, HIPS, PET and more.

Recommend mainly for In-house, Post-industrial clean plastic rigid materials, including crushed bottles, crushed industrial waste and injection materials.

| Model | RF-85 | RF-100 | RF-125 | RF-135 | RF-150 | RF-175 |

|---|---|---|---|---|---|---|

| Main Extruder | ∮85mm | ∮100mm | ∮125mm | ∮135mm | ∮150mm | ∮175mm |

| Main Drive | 75 HP | 125 HP | 175 HP | 200 HP | 250 HP | 300 HP |

| Output (kg/hr) | 200-300 | 300-400 | 450-600 | 650-850 | 700-800 | 900-1100 |

| Optional Devices: Horizontal mixer Tank, Screw conveyor, Masterbatch feeder, Vacuum pump, Doble vented barrel, Dual piston filter, Cooling tower with tank for water circulation. |

||||||