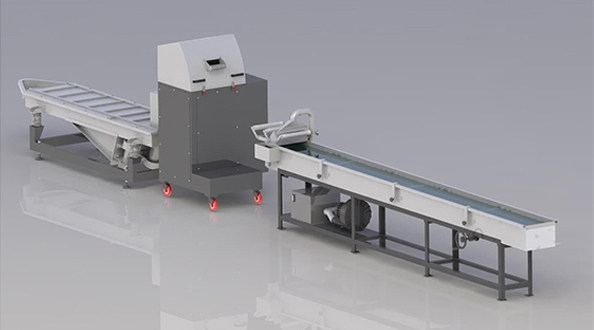

3 In 1 Type Two Stage Cutter Compactor Plastic Recycling Machine

Integrate the cutting, extrusion and pelletizing in one machine which saving the space and working efficiently.

The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processing. Increase the highest throughputs for more productivity.

In compare with crusher system, the cutter compactor works with low noise which provides the friendly working environment.

Triple cooling sections – air cooling system, compactor body water cooling system, and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature.

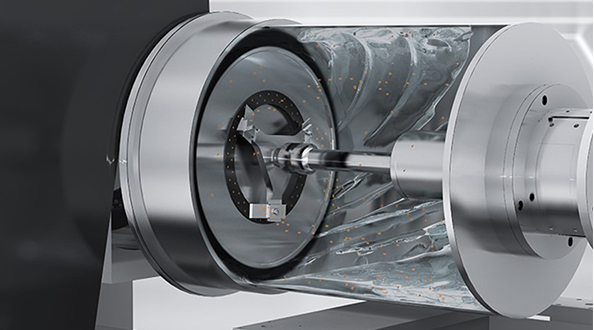

The unique development of a two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke.

Up to triple optional degassing zones equipped with vacuum pumps. Maximize the degassing efficiency for moisture or printed materials which is favor of mixing more percentage of the recycled material for post-processing.

Energy cost saves up to 20%

Labor cost is reduced as only 1~2 operators are needed to operate the whole plant.

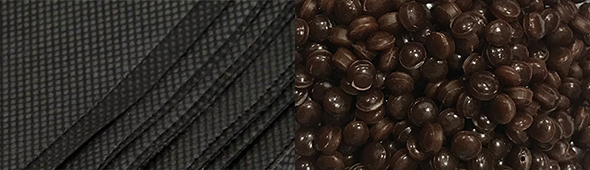

The pelletizing system can equip with hot die face cutting water cooling system or Strand (Spaghetti) pelletizing system depends on the material property and material Melt Index.

| Model | RS2-100 | RS2-125 | RS2-135 | RS2-150 | RS2-175 | |

|---|---|---|---|---|---|---|

| Main Extruder | Screw | ∮100mm | ∮125mm | ∮135mm | ∮150mm | ∮175mm |

| Drive | 125 HP | 175 HP | 200 HP | 250 HP | 300 HP | |

| Sub Extruder | Screw | ∮125mm | ∮155mm | ∮155mm | ∮165mm | ∮200mm |

| Drive | 40 HP | 75 HP | 100 HP | 100 HP | 150 HP | |

| Compactor Drive | 75 HP | 100 HP | 125 HP | 150 HP | 175 HP | |

| Output (kg/hr) | 300-400 | 450-600 | 650-850 | 700-800 | 900-1100 | |

| Optional Devices: Metal detector, Nip roller for feeding film roll , Masterbatch feeder, Vacuum Pump, Doble Vented Barrel, Dual piston filter, Cooling tower with tank for water circulation. |

||||||